Sawdust Roller Shell

When it comes to pellet production, the quality of the roller shell plays a vital role in the efficiency of the process. Among the different types of roller shells available, the sawdust roller shell is a popular choice for many pellet manufacturers.

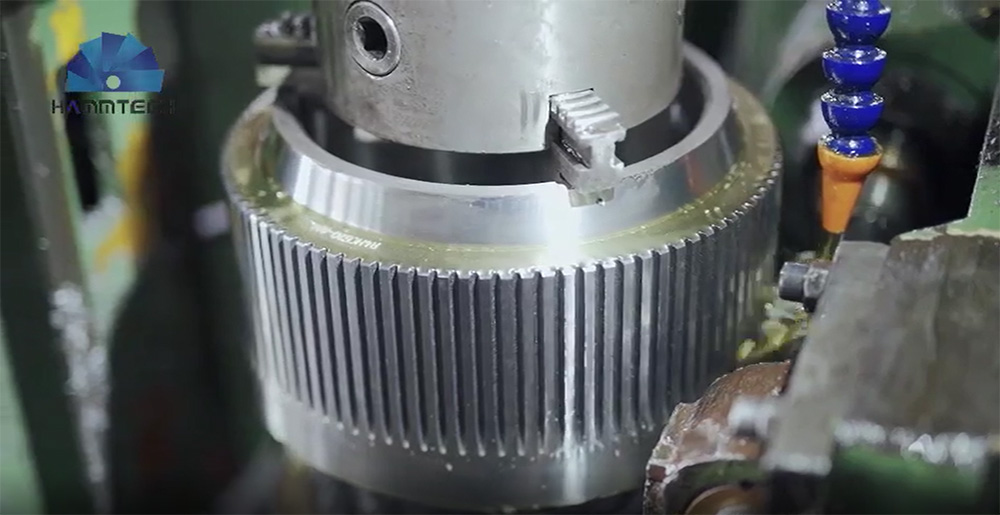

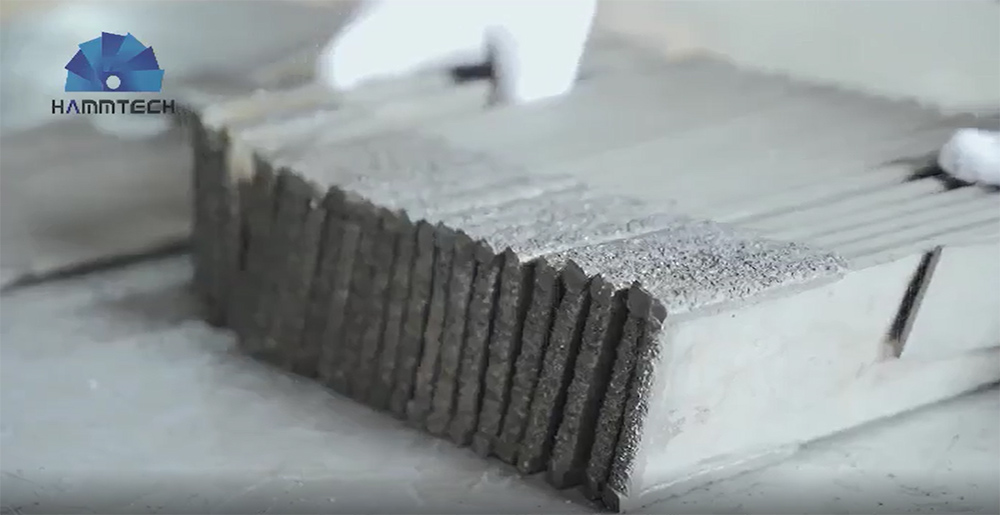

A sawdust roller shell is a type of roller shell used in pellet mills. The roller shell is the outer covering of the pellet mill's rollers, and it is responsible for compressing the raw material into small pellets. The sawdust roller shell is made from high-quality steel and features a series of sawtooth-like grooves on its surface.

The sawtooth-like grooves on the surface of the sawdust roller shell play a crucial role in the pellet production process. As the roller shell rotates, the grooves help to create friction between the roller and the raw material. This friction generates heat, which softens the material and makes it easier to compress into pellets.

There are several types of roller shells available for pellet mills, including smooth roller shells, dimpled roller shells, and corrugated roller shells. While each of these roller shells has its advantages, the sawdust roller shell stands out for several reasons:

1. Improved Pellet Quality: The sawtooth-like grooves on the surface of the sawdust roller shell help to compress the raw material evenly, resulting in pellets of consistent quality.

2. Reduced Wear and Tear: The sawtooth-like design of the roller shell also helps to prevent slippage between the roller and the raw material. This reduces the amount of wear and tear on the roller shell, increasing its lifespan.

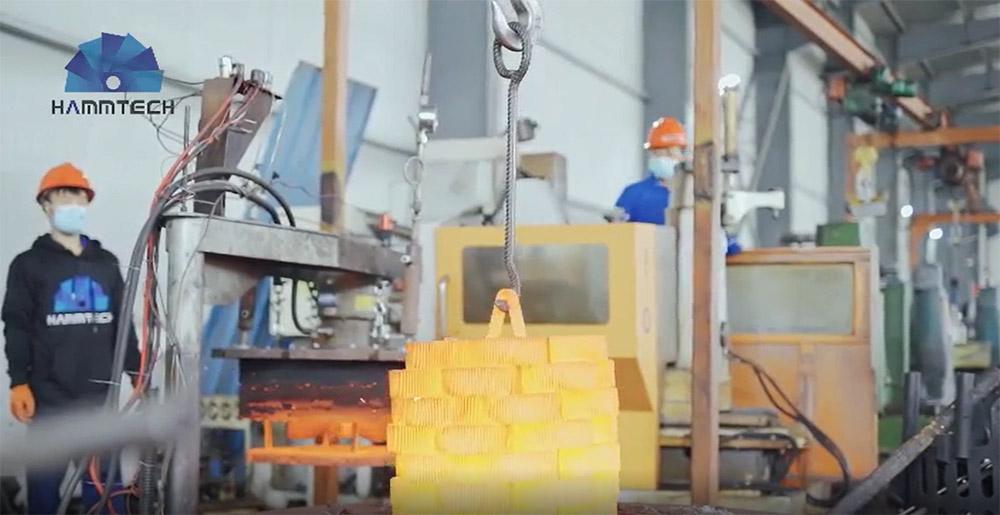

3. Increased Efficiency: Because the sawdust roller shell generates heat as it compresses the raw material, it reduces the amount of energy required to produce high-quality pellets.

4. Versatility: The sawdust roller shell can be used to produce a wide range of pellets, including those made from sawdust, wood chips, straw, and other biomass materials.