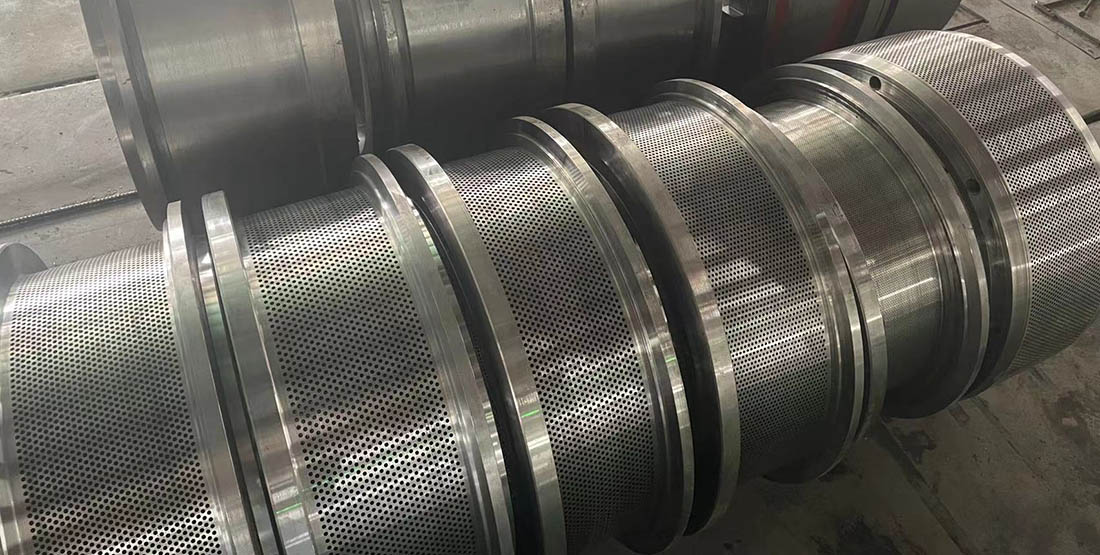

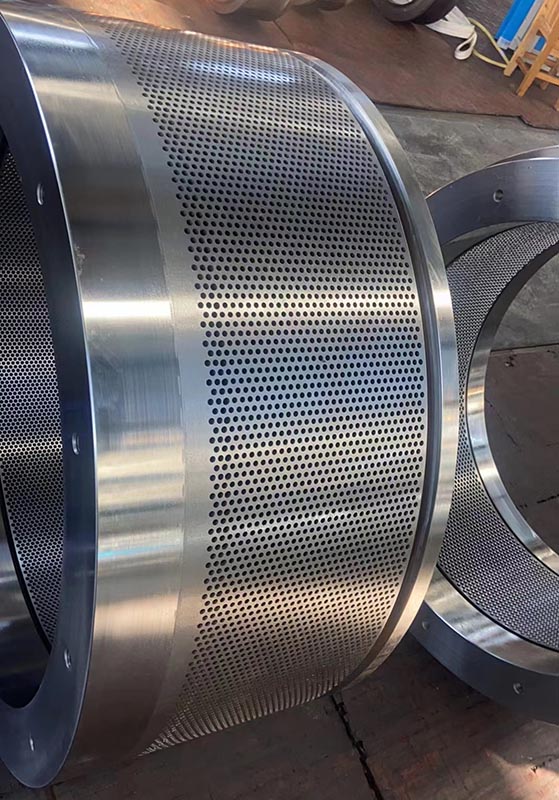

Ring Die

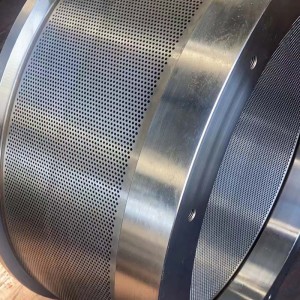

① The ring die must be stored in a dry, clean, and ventilated place with good specification markings. If it is stored in a humid place, it may cause corrosion of the ring die, which may reduce the service life of the ring die or affect the discharge effect.

② Generally, there are a lot of production materials in the workshop, do not put the ring die in these places, because the materials are particularly easy to absorb moisture and not easy to disperse, if put together with the ring die, it will accelerate the corrosion of the ring die, thus affecting its service life.

③ If the ring dies are not to be used for a long period of time, it is recommended to coat the surface of the ring dies with a layer of waste oil, so as to prevent the corrosion of moisture in the air.

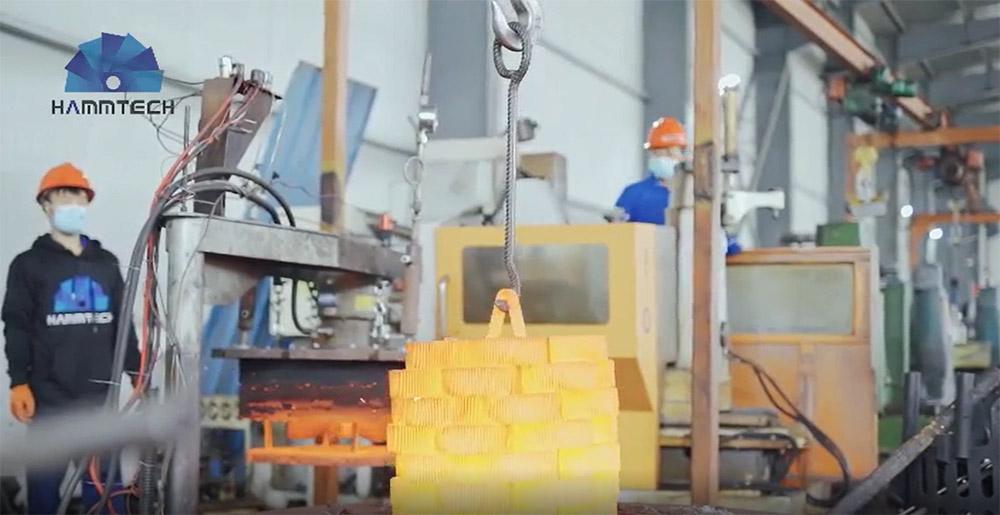

④ When the ring die is stored for more than 6 months, the oil filling inside needs to be replaced with new one. If stored for too long, the material inside will harden and the granulator will not be able to press it out when used again, thus causing a blockage.

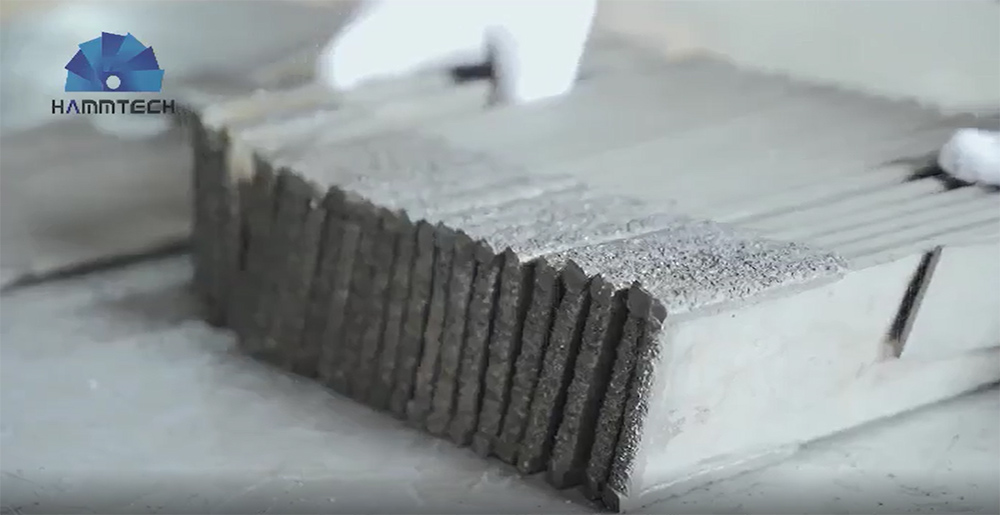

1. When the ring die is not used for a period of time, the original feed should be extruded out with non-corrosive oil, otherwise, the heat of the ring die will dry out and harden the feed originally left in the die hole.

2. After the ring die has been in use for a while, the inner surface of the die should be checked to see if there are any local projections. If this is the case, a polisher should be used to grind off the projections to ensure the output of the ring die and the service life of the pressure roller.

3. If the die hole is blocked and no material comes out, it can be re-granulated by oil immersion or oil boiling, and if it still cannot be granulated, the blocked material can be drilled out with an electric drill and then polished with oily material and fine sand.

4. When loading or unloading the ring die, the surface of the die should not be pounded with hard steel tools such as hammers.

5. A record of the use of the ring die should be kept for each shift so that the actual service life of the die can be calculated.