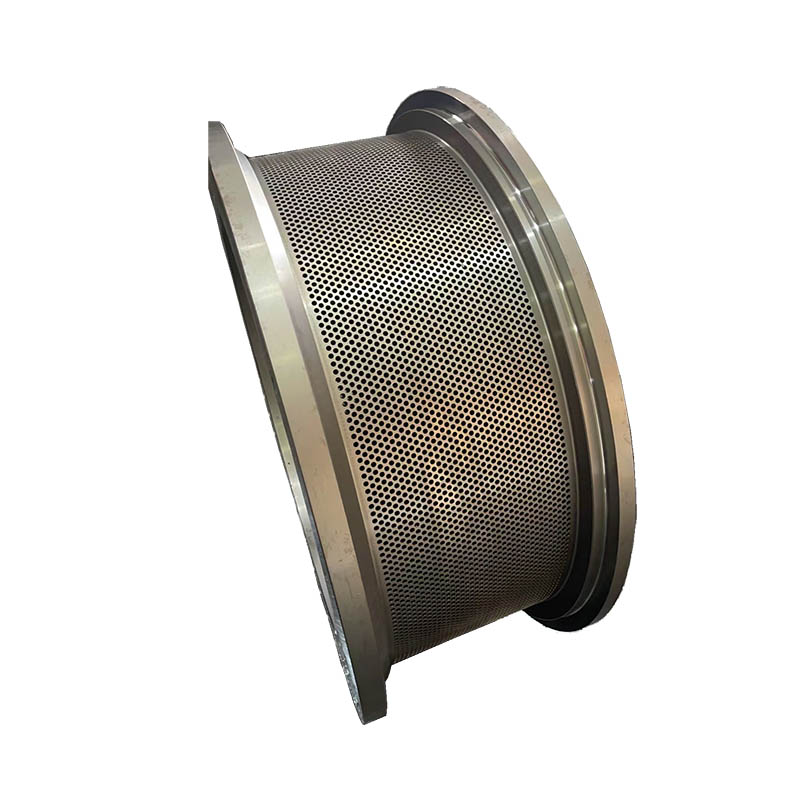

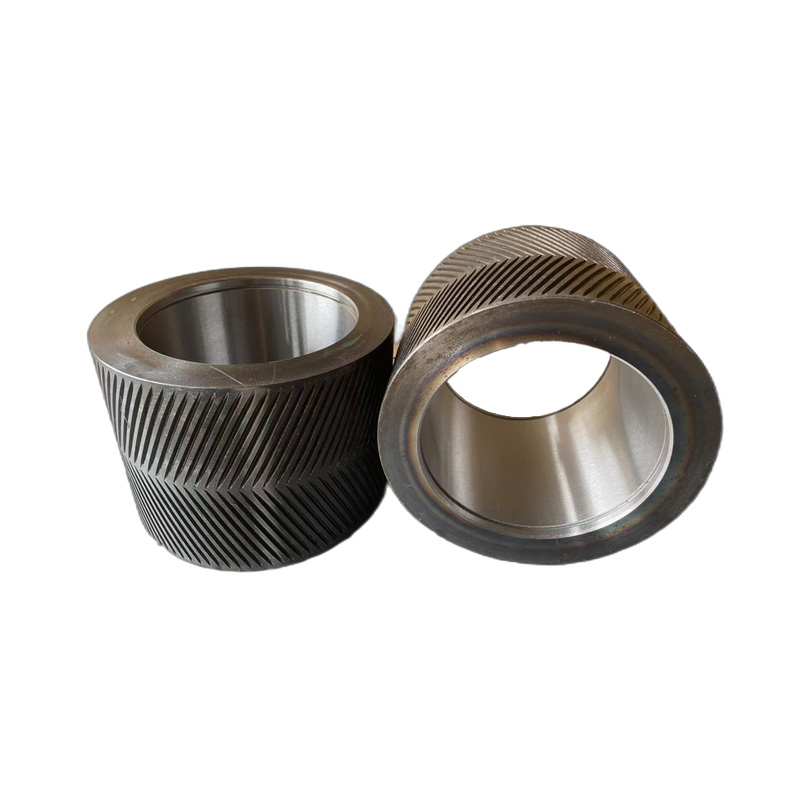

Roller Shell Shaft of Pellet Mill

The primary function of a roller shell shaft is to provide a rotating axis for the roller shell, which is typically a cylindrical component used to support and guide material being conveyed. The roller shell shaft performs several important functions, including:

1. Supporting Loads: The roller shell shaft is designed to support the weight of the material being conveyed, as well as any additional loads that may be imposed on the system, such as friction or impact.

2. Maintaining Alignment: The roller shell shaft helps to maintain the proper alignment of the roller shell and the material being conveyed, ensuring that the material moves smoothly and efficiently.

3. Reducing Friction: The smooth surface of the roller shell shaft helps to reduce friction between the roller shell and the shaft, which can increase the lifespan of the roller shell and the overall efficiency of the system.

4. Providing Rotational Movement: The roller shell shaft provides a rotating axis for the roller shell, allowing it to rotate and convey material.

5. Absorbing Impact: In some applications, the roller shell shaft may also be designed to absorb impact and vibrations, helping to protect the material being conveyed and other components in the system.

6. Transferring Torque: In some systems, the roller shell shaft may also be used to transfer torque from a drive mechanism to the roller shell, allowing it to rotate and convey material.

In summary, the roller shell shaft is a critical component in many mechanical systems, serving several important functions that are essential to the proper operation of the system.

Regular maintenance of the roller shell shaft is crucial to ensure it operates efficiently and lasts longer. This includes checking for proper lubrication, tightness of bolts, and signs of wear and tear. Remember to lubricate the shaft regularly according to the manufacturer's recommendations. Avoid overloading and excessive speed. Always follow the manufacturer's recommendations for maximum load capacity and operating speed. With all these in mind, you can keep the shaft running efficiently and longer.