Products

-

Roller Shell Shaft Bearing Spare Parts

● Strong load-bearing capacity;

● Corrosion resistance;

● A smooth surface finish;

● Size, shape, diameter customized.

-

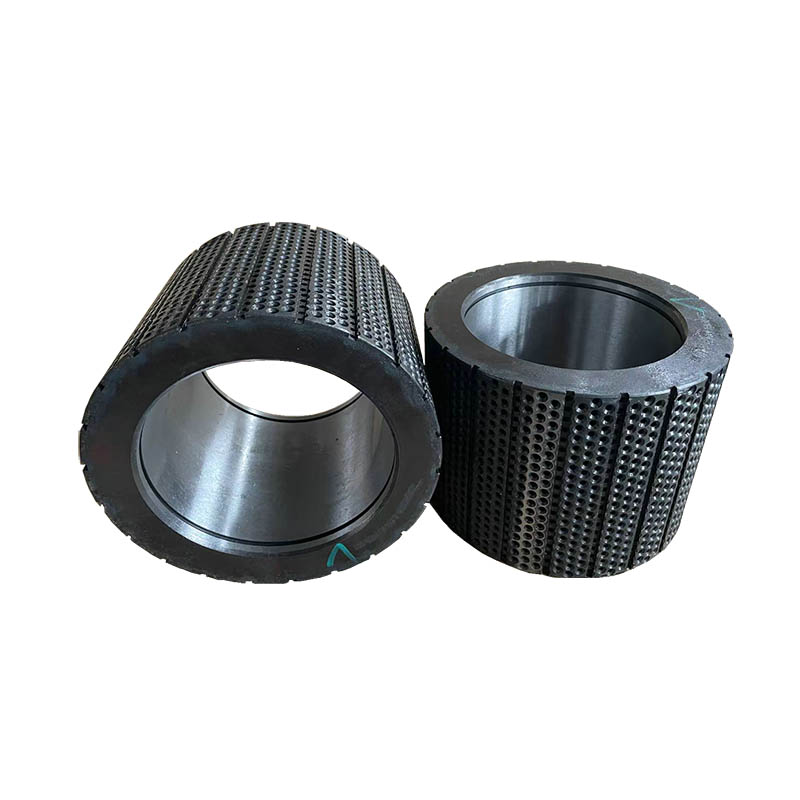

Dimpled Roller Shell for Pellet Machine

This roller shell adopts a new process to add hole teeth to the straight teeth of the whole body of the roller shell. Double tooth type staggered combination. Secondary heat treatment process. Greatly enhanced the hardness and wear resistance of the roller shell.

-

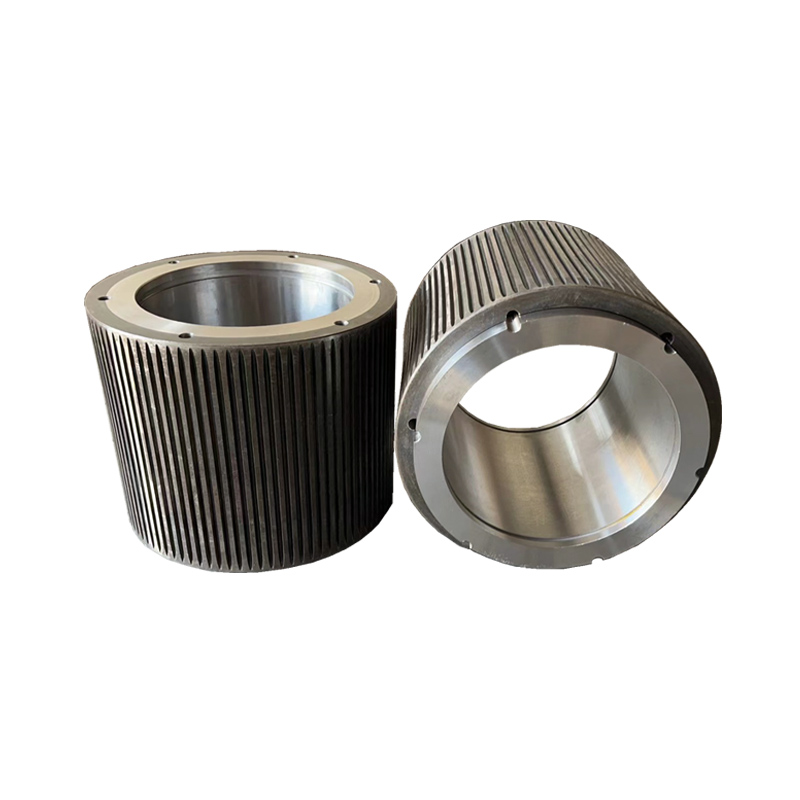

Closed-End Roller Shell for Pellet Mill

The world’s original and innovative technology. The outer layer of the pressure roller shell can be removed and replaced, and the inner layer can be reused, saving the cost of use and creating additional value.

-

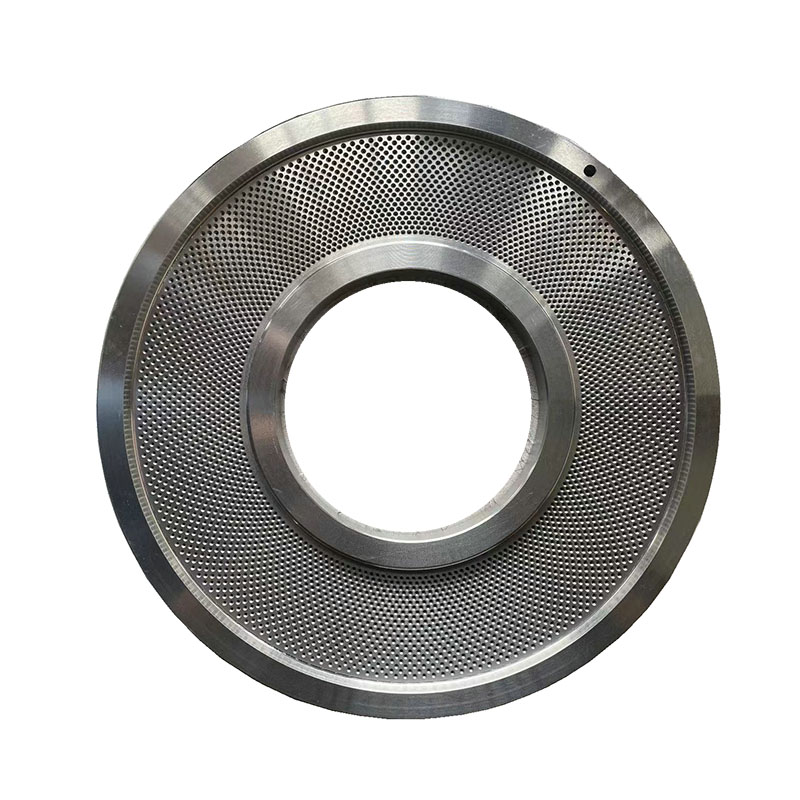

Biomass and Fertilizer Pellet Mill Ring Die

• High-quality alloy steel or stainless steel

• Extremely precise manufacture

• High hardness after heat treatment

• Durable for high impact, pressure, and temperature

-

Shrimp Feed Pellet Mill Ring Die

1. Material: X46Cr13 /4Cr13(stainless steel), 20MnCr5/20CrMnTi (alloy steel) customized

2. Hardness: HRC54-60.

3. Diameter: 1.0mm up to 28mm;Outer diameter: up to 1800mm.

We can customize different ring dies for many brands, such as CPM, Buhler, CPP, and OGM. -

Manufacturer of Hammermill Accessories and Pelletmill Accessories

Changzhou Hammermill Machinery Technology Co., Ltd. (HAMMTECH) is a factory specializing in the production of feed machinery’s spare parts. We can manufacture the big gear and small gear of various pellet mill, hoop die clamp, spacer sleeve, gear shaft, and different kinds of ring die, roller shell, roller shell shaft, and roller shell assembly according to the customer’s drawings.

-

Tungsten Carbide Sawdust Hammer Blade

This tungsten carbide hammer blade used for wood crusher is made of low alloy 65 manganese as the base material, with high hardness and high tungsten carbide overlay welding and spray welding reinforcement, which makes the performance of the product better and higher.

-

Tungsten Carbide Blade of Sugar Cane Shredder Cutter

This kind of tungsten carbide blade adopts a hard alloy which has the properties such as high hardness, wear resistance and high corrosion resistance. It helps to make the sugar cane shredding more efficient.

-

3MM Tungsten Carbide Hammer Blade

We can produce tungsten carbide hammer blades with different sizes. Manufactured from high-quality forged steel and finished with advanced hardfacing technology, our hammer blades are designed to meet the most demanding applications.

-

Double Hole Smooth Plate Hammer Blade

Hammer blade is the most important part of hammer mill. It keeps the efficient operation of hammer mill, but it is also the most easily worn part. Our hammer blades are made of high-strength carbon steel and are designed for the most demanding applications with industry-leading hardfacing technology.

-

Pellet Mill Flat Die

Material

The type of steel used for manufacturing is a key factor in the durability of the final product. High quality wear-resistant alloy steel with high wear resistance and durability shall be selected, including 40Cr, 20CrMn, stainless steel, etc.