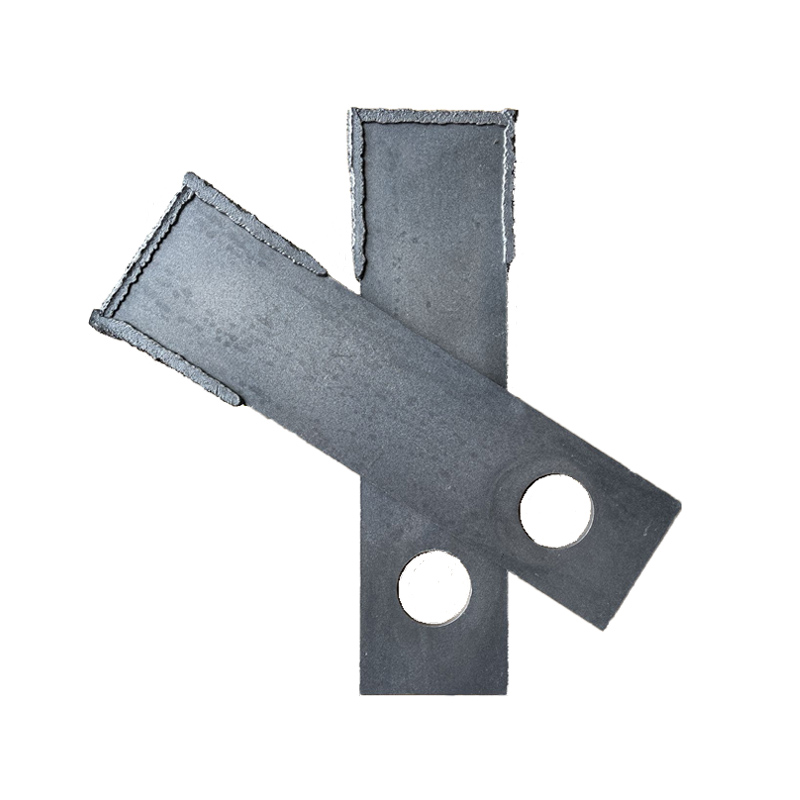

Flat Overlay Welding Hammer Blade With Tungsten Carbide

A 16mm-wide wear-resistant layer is deposited on the hammer surface. The wear-resistant layer and the base material have a 16mm welding interface, ensuring strong adhesion without detachment. Meanwhile, the toughness of the base material is preserved, preventing breakage. This product is particularly suitable for handling materials with high sand and stone content. Specifically designed for industries such as alcohol production, mining, and waste processing, it has achieved excellent performance.

Basic hammer blade

With a 16mm wide wear-resistant surfacing layer welded on the top. 3mm wear-resistant welding layer on both sides.

Strengthen hammer blade

With a 3mm wide wear-resistant overlay layer on the top. 16mm wear-resistant weld overlay on both sides.

Super hammer blade

With a 16mm wide wear-resistant overlay layer on the top and both sides.

Customizable specifications and styles, with a good reputation and high cost-effectiveness.