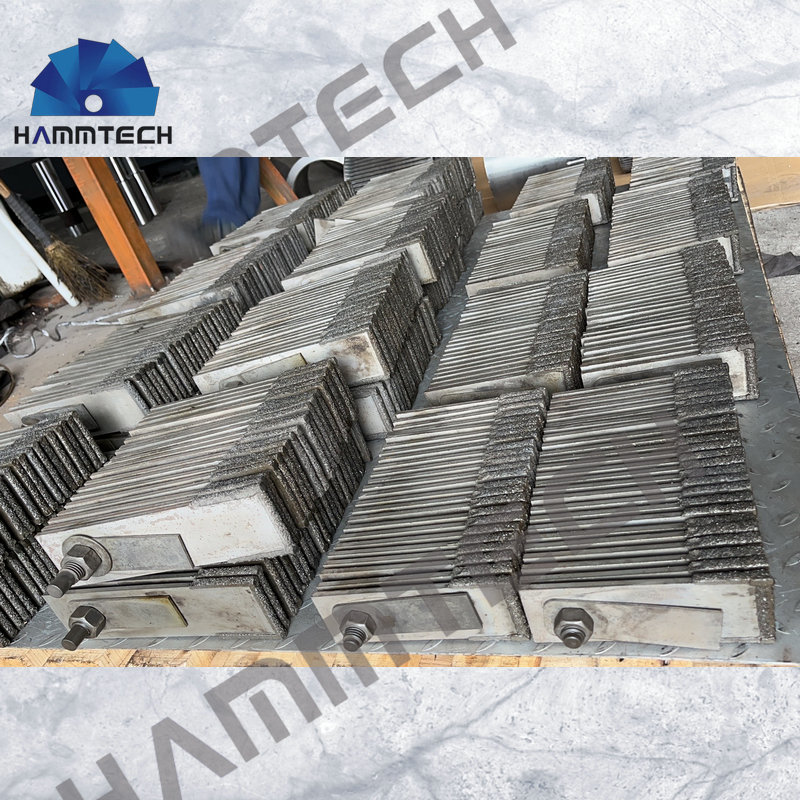

Hammer mill beater is a necessary equipment for the pre-production of many industries, especially the pharmaceutical, feed, food, paint, and chemical industries. Hammer mill beater has a wide range of versatility, can adjust the crushing fineness, has the advantages of high production efficiency, low energy consumption, safe use, convenient maintenance, etc., so it has been favored by all walks of life.

Working principle

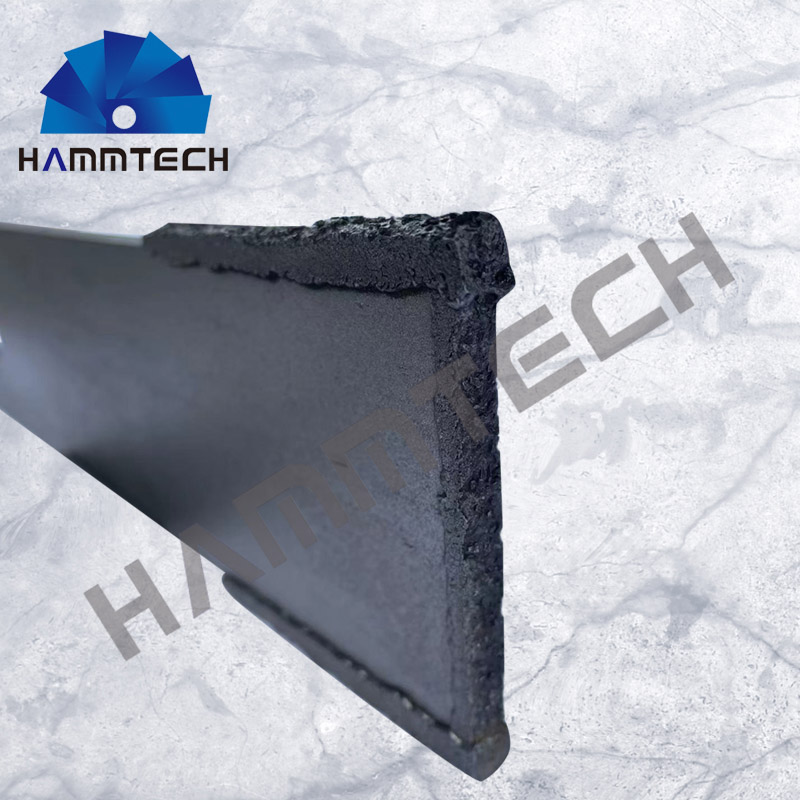

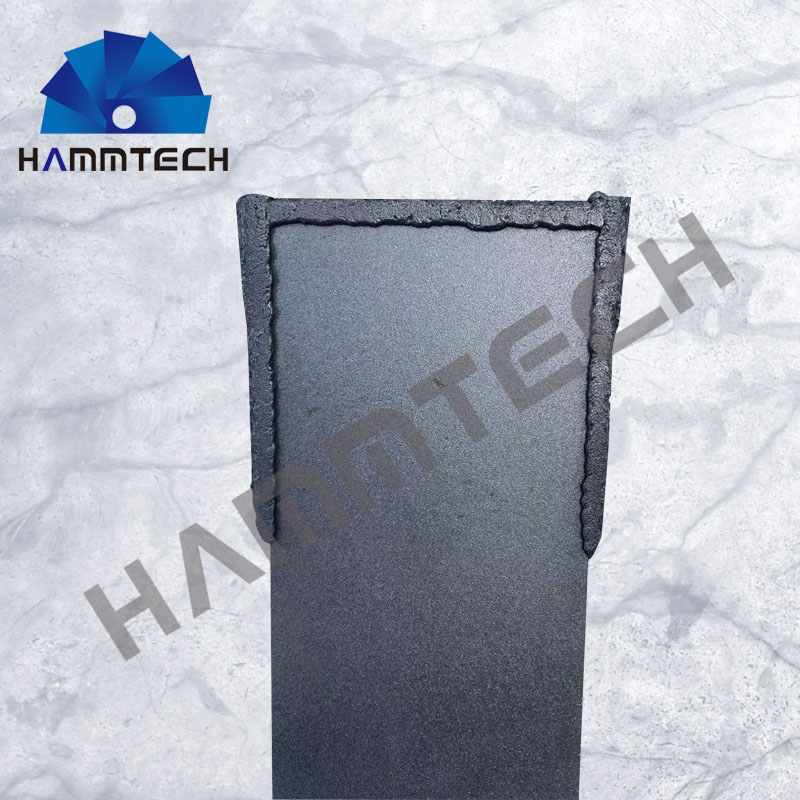

Hammer mill beater mainly relies on impact to break materials. The material enters the hammer mill and is crushed by the impact of the high-speed rotating hammer head. The crushed material obtains kinetic energy from the hammer head of the hammer crusher and rushes to the baffle plate and screen bar in the frame at high speed. At the same time The materials collide with each other and are crushed many times. The materials smaller than the gap between the screen bars are discharged from the gap. Individual larger materials are impacted, ground, and squeezed by the hammer on the screen bar again, and the material is crushed by the hammer. The hammer head of the breaker squeezes out from the gap. In order to obtain the desired particle size of the product.

The crushing effect of hammer mill beater is mainly evaluated by three indicators, such as crushing fineness, output per unit time of crushing, and unit energy consumption of the crushing process. These indexes depend on the physical properties of the crushed material, the structure of the crusher, Factors such as the shape of the crushing chamber, the number, thickness and line speed of the hammers, the shape and diameter of the screen hole, the gap between the hammers and the screen surface, etc.

Post time: Dec-01-2022