The hammer beater manufacturer tells you that the hammer is the most important and most easily worn working part of the crusher. Its shape, size, arrangement method, manufacturing quality, etc. have a great influence on the crushing efficiency and product quality.

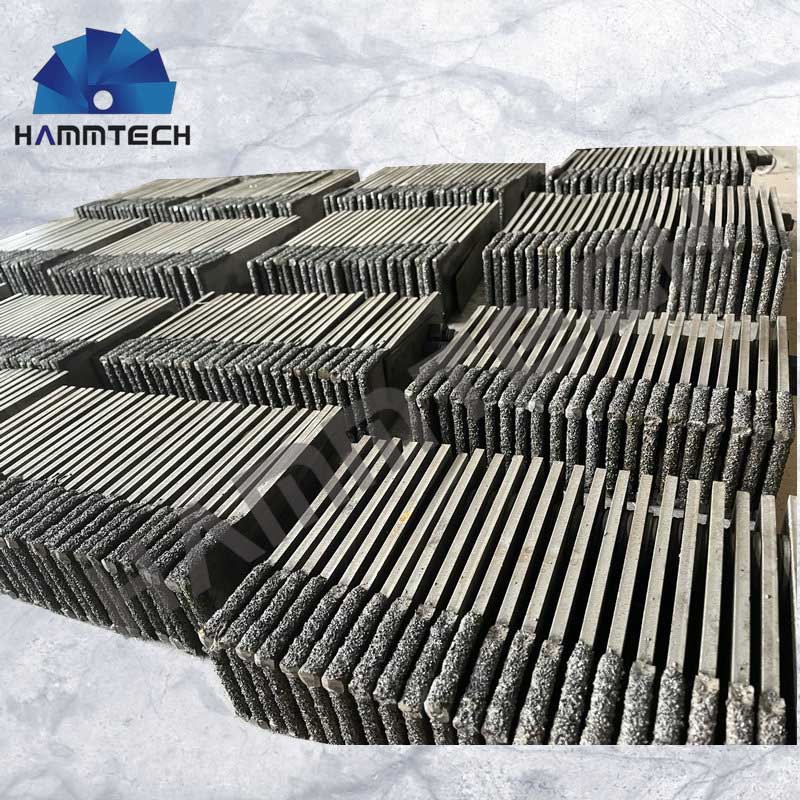

The hammer beater manufacturer tells you that there are many shapes of hammers currently used, but the most widely used is the plate-shaped rectangular hammer, because it has a simple shape, is easy to manufacture, and has good versatility. It has two pin shafts, one of which is threaded on the pin shaft, and the four corners can be used in rotation to work. Coating welding, surfacing welding tungsten carbide or welding a special wear-resistant alloy on the working side to prolong the service life, but the manufacturing cost is relatively high. Poor abrasion resistance. The annular hammer has only one pin hole, and the working angle is automatically changed during work, so the wear is uniform and the service life is long, but the structure is complicated. The hammer beater manufacturer tells you that the composite steel rectangular hammer is a steel plate with high hardness on the two surfaces and good toughness in the interlayer provided by the rolling mill. It is simple to manufacture and low in cost.

The manufacturer of hammer beater tells you that the test shows that the appropriate length of the hammer is conducive to increasing the output of electricity per kilowatt-hour, but if it is too long, the metal consumption will increase and the electricity output per kilowatt-hour will decrease.

Post time: Dec-20-2022